SPM automatic feeding tapping machine

This series of products is fully metal tapping to achieve automatic tapping machinery and equipment, widely used in some hardware, nuts, nuts and other non-standard hardware tapping, tapping, die and other processing. The use of gear-type automatic tapping machine tapping machine head to ensure the accuracy of the thread to ensure that pass through the rules of detection, there are pneumatic and hydraulic cylinder as a folder power to ensure that automatic tapping machine tapping machine in the clip material that can ensure clamping But also to ensure that the product is not caught, to ensure the absolute safety of equipment operation, with easy installation and maintenance, beautiful, safe, easy to operate and so on.

Application areas: for small hardware need high-speed automatic tapping machine processing.

Inquire Now

- Technical Data

- Dimensions

- Products Featrue

- Accessries

- Application Gallery

This series of products is fully metal tapping to achieve automatic tapping machinery and equipment, widely used in some hardware, nuts, nuts and other non-standard hardware tapping, tapping, die and other processing. The use of gear-type automatic tapping machine tapping machine head to ensure the accuracy of the thread to ensure that pass through the rules of detection, there are pneumatic and hydraulic cylinder as a folder power to ensure that automatic tapping machine tapping machine in the clip material that can ensure clamping But also to ensure that the product is not caught, to ensure the absolute safety of equipment operation, with easy installation and maintenance, beautiful, safe, easy to operate and so on.

Application areas: for small hardware need high-speed automatic tapping machine processing.

Automatic machine | SYT T8 | SYT T16 | SYT T32 |

Feeding system | Stainless steel vibration plate | Stainless steel vibration plate | Stainless steel vibration plate |

Spindle travel (MM) | 45 | 65 | 65 |

Processing capacity | M2-M8 | M5-M16 | M10-M32 |

Spindle speed | 500-1600 | 300-700 | 80-400 |

Spindle taper | B16 | B18 | B25 |

Motor Power | 0.75KW | 1.5KW | 3.0KW |

Dimensions(MM) | 1200X1100X1500 | 1200X1200X1600 | 1200X1400X1700 |

Net Weight (KG) | 450 | 550 | 700 |

Control System | PLC + 7 inch touch screen | PLC + 7 inch touch screen | PLC + 7 inch touch screen |

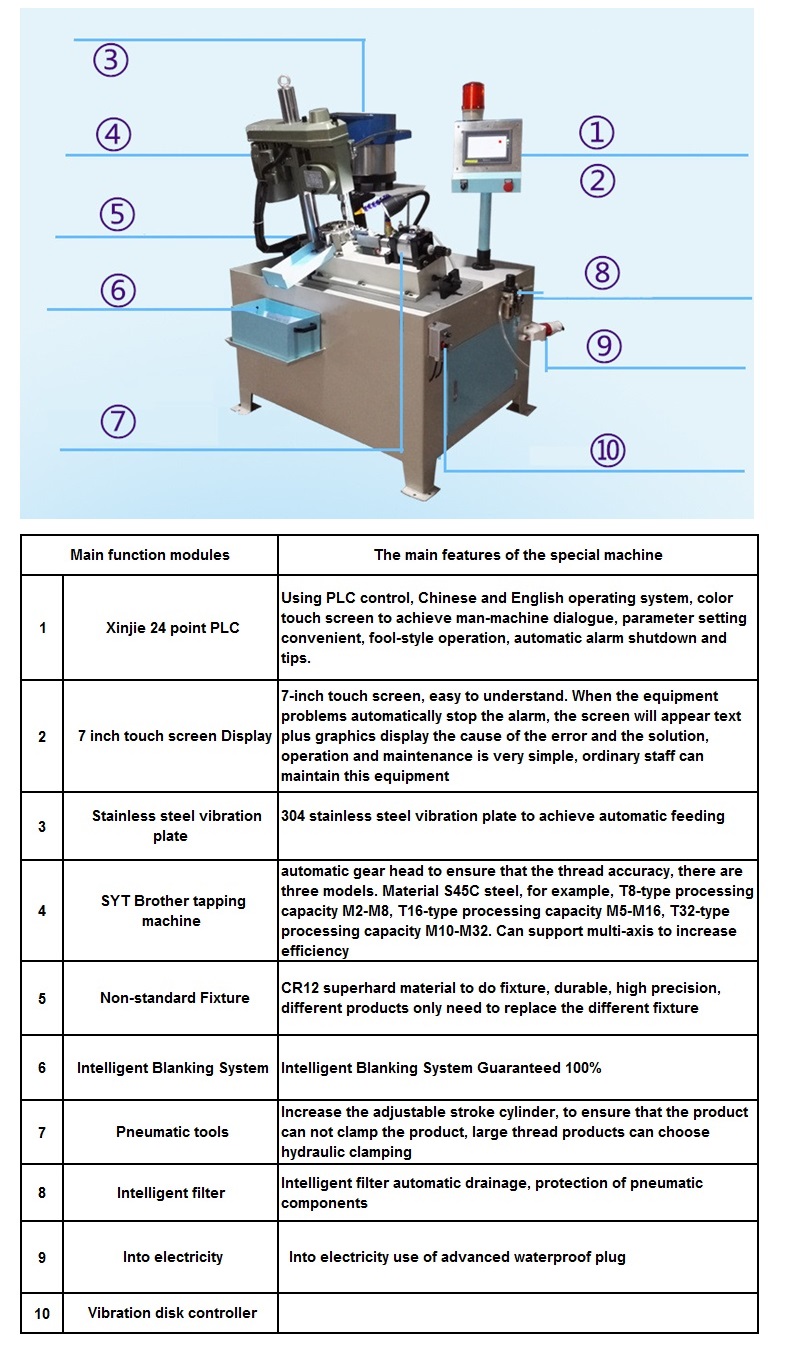

Features:

★ equipment standard: No material automatically shut down, blind hole automatic shutdown, and tap broken automatic shutdown alarm function. Is the industry's most complete function of the automatic tapping machine manufacturers

★ using PLC control, the use of Chinese color touch screen to achieve man-machine dialogue, parameter settings convenient, fool-like operation, automatic alarm shutdown and the Chinese prompt. ;

★ This equipment is tailored according to your company's product design, good stability, low investment, high efficiency, processed products with high precision, large quantity, cost recovery cycle is short;

★ all the action by the software control, flexible device parameters set to facilitate the functional adjustment and technology upgrades, never backward;

★ This device is not easy to damage the tap. Taps wear, failure equipment automatically alarm shutdown and Chinese or English tips error report, will not appear rotten teeth, bad teeth, limit the occurrence of defective products, fault self-diagnosis function, fault display at a glance;

★ drive system is simple and concise, work more stable, more convenient maintenance, failure rate is very low, low power consumption equipment;

★ easy to replace the fixture can be used for a variety of similar products share this device;

★ the entire equipment in a fully automated, one can operate multiple devices at the same time;

Security Intelligent Design:

★ with leakage protection and lack of protection device.

★ system with intelligent alarm system, a problem Automatic tapping machine tapping machine equipment automatically shut down alarm and intelligent error report.

★ This device does not have any requirements on the tool, you can use the cutting tap, you can also use the extrusion tap for automatic tapping automatic tapping.

Strong after - sales service

★ to ensure full automatic machine automatic tapping machine automatic drilling machine packaging in line with moisture, rain, rust, corrosion and shock requirements, logo clear and correct, so that items safe and timely arrived at the scene.

★ In order to better ensure the normal operation of CNC drilling machine, timely answers to questions raised by users to help users solve the problem, the company ad hoc maintenance center, responsible for all over the equipment maintenance and technical advice and other services. Maintenance center by the full-time engineers at any time for customers free of charge to provide technical advisory services.

★warranty period: the contract under the equipment warranty for the installation and commissioning of 12 months after the success. Wearing parts warranty 6 months, the warranty period (except for force majeure factors and man-made damage) spare parts costs, travel costs are borne by the supplier.

★ my company to provide users with free software upgrades. As the user's special requirements and process changes, need to change the PLC program or computer program, our company is responsible for changes, charge software fees.