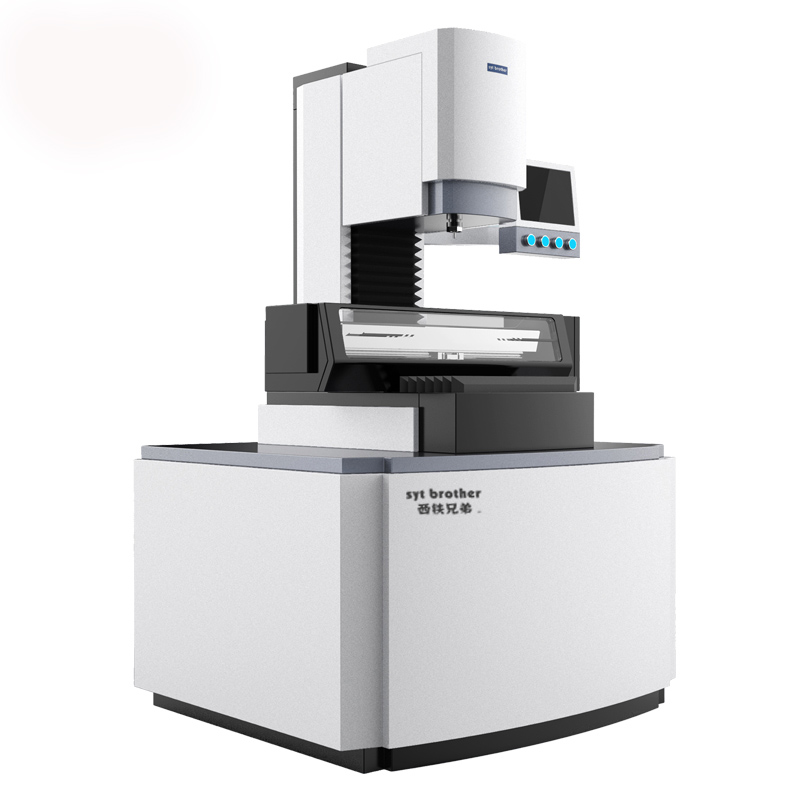

SYT 420 Miniature Threads Tapping Machine

Take S45C workpieces as en example, the SYT 420 Miniature Threads Tapping Machine tapping machine is design for making M0.6-M5 thread. Can be used to match multi-axis device.

Inquire Now

- Products Featrue

- Technical Data

- Detailed Presentation

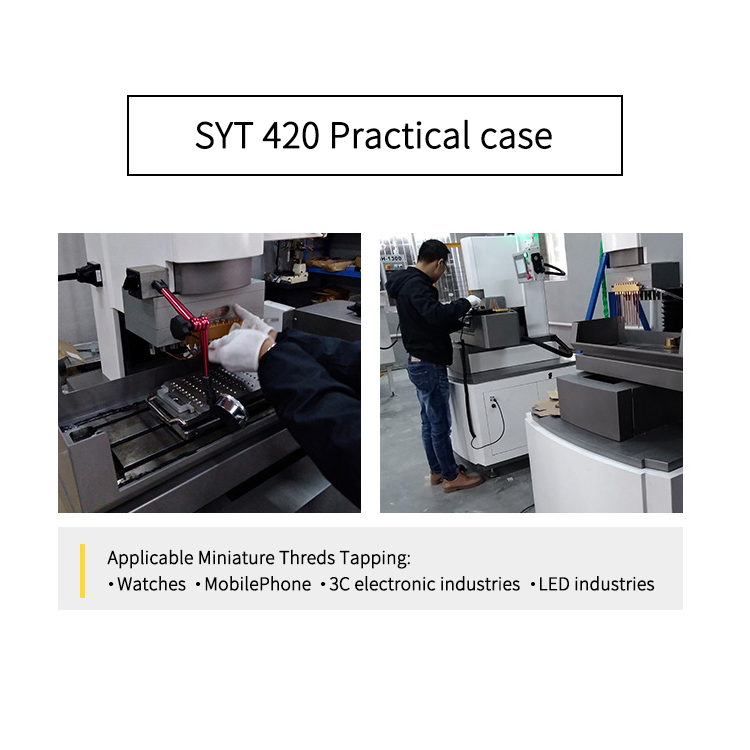

- Application Gallery

- Standard Equipment

Automatic torque control allows for multi-step adaptive tapping perations.

Ultra high speed peck-drilling with feed rate up to 5 m/min.

Drilling and tapping are accomplished at a time without need of tool change.

Smart abnormal torque checking and repetitive machining not only provides tool-wear montioring,but also prevent defective parts from flowing out.

Capable of repetitive tapping for high ahesion materials,such as ceramic,without

double threads tapping problem.

Dialogue,matrix and teaching input without need of G,M code input.

| Item | SYT 420 |

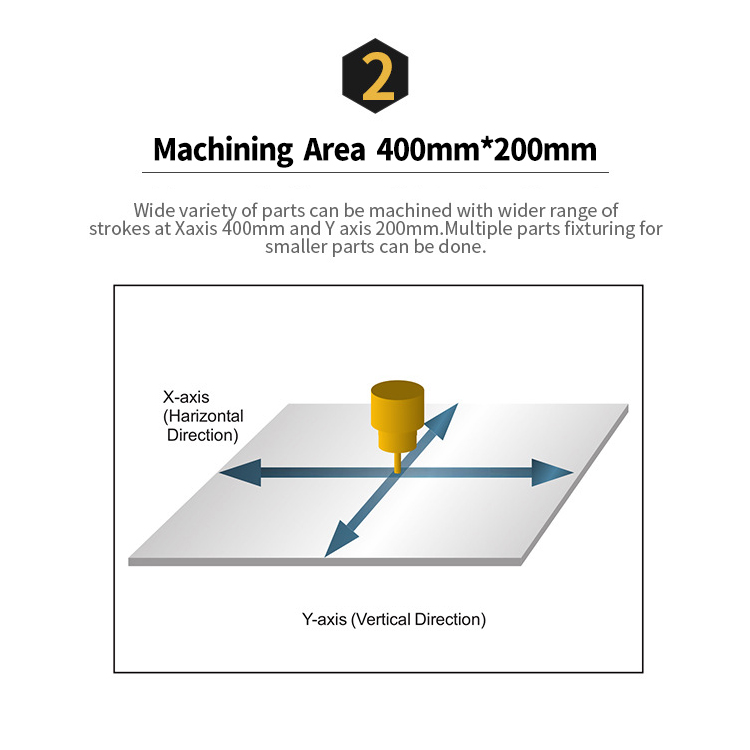

| Travel(X/Y/Z) | 400/200/200mm |

| Rapid travel | 10m/min |

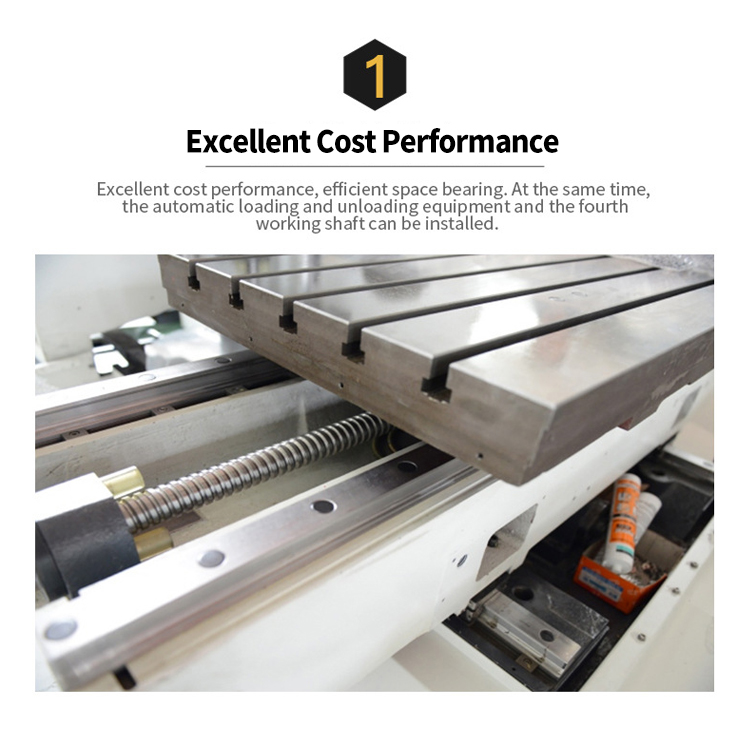

| Woking table | 400*200mm 150KG |

| Spindle travel | 200mm |

| Spindle taper | ER16 |

| Max spindle speed | 5000rpm |

| Tapping capacity | M0.6-M5 |

| Drilling capacity | φ0.2-φ6mm |

| Motor(X/Y/Spindle) | 400/400/750W |

| Power supply | 220V 3KVA |

| Machine weight | 400KG |

| Machine space required(L*W*H) | 1000/1000/1800mm |

Standard Equipment:

●Cutting coolant system

●φ3 collet

●3-color imdication lamp

●Semi-enclosed splash guard

●MPG unit

●Working light

●Automatic lubrication system

●Tool box

●Moving Castors